Kodi IXPE/PP ndi chiyani

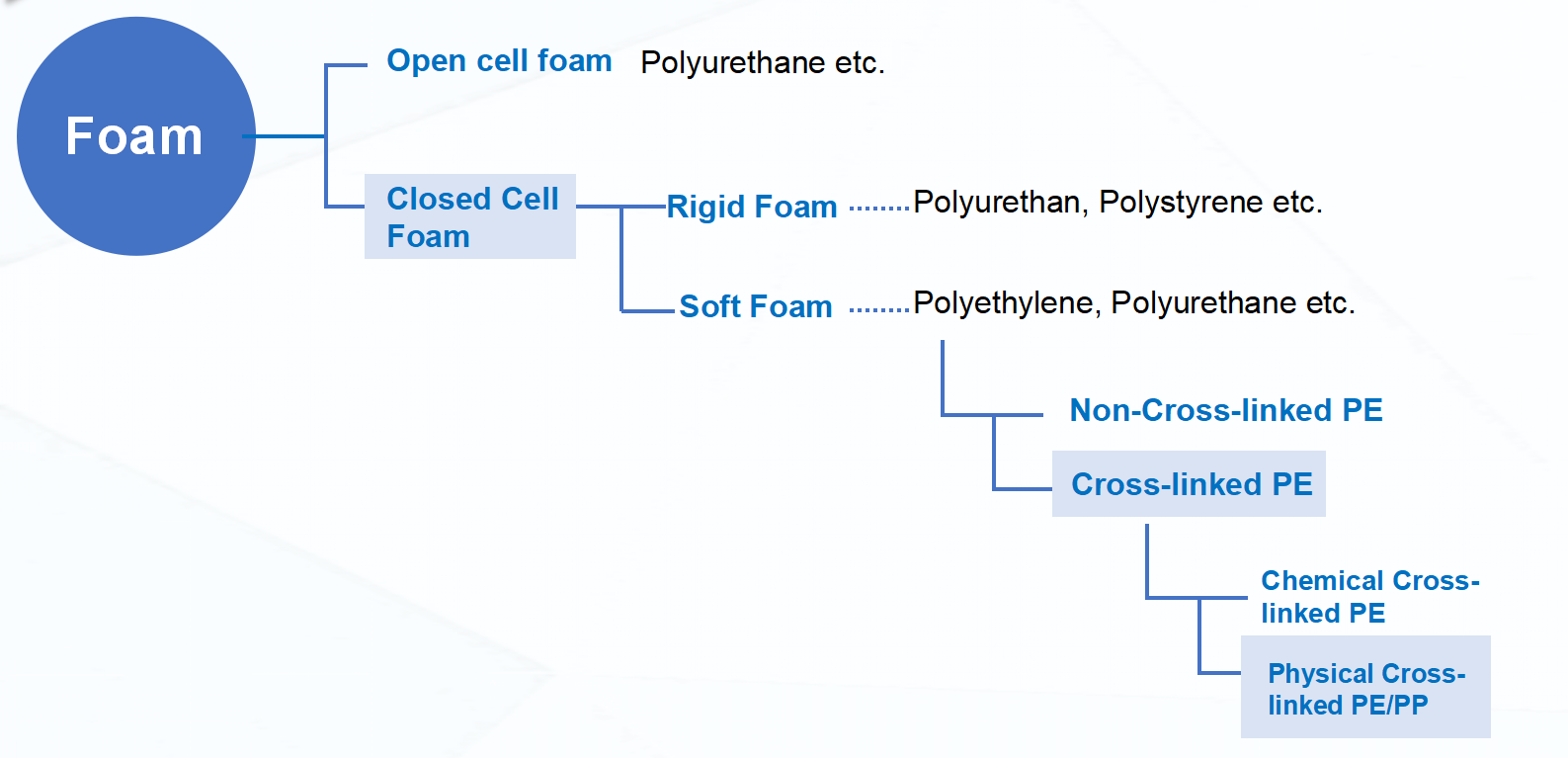

Chithovu

Chithovu ndi mtundu wa zinthu zapulasitiki zomwe thovu la mpweya limamwazikana kuti likhale lobowola.Chithovu chimakhala ndi mpweya wambiri ndipo motero ndi chopepuka komanso chabwino kwambiri pakumangirira ndi kutchinjiriza kwamafuta.

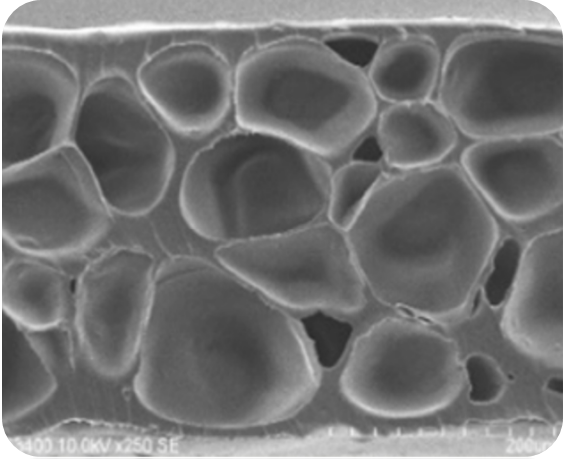

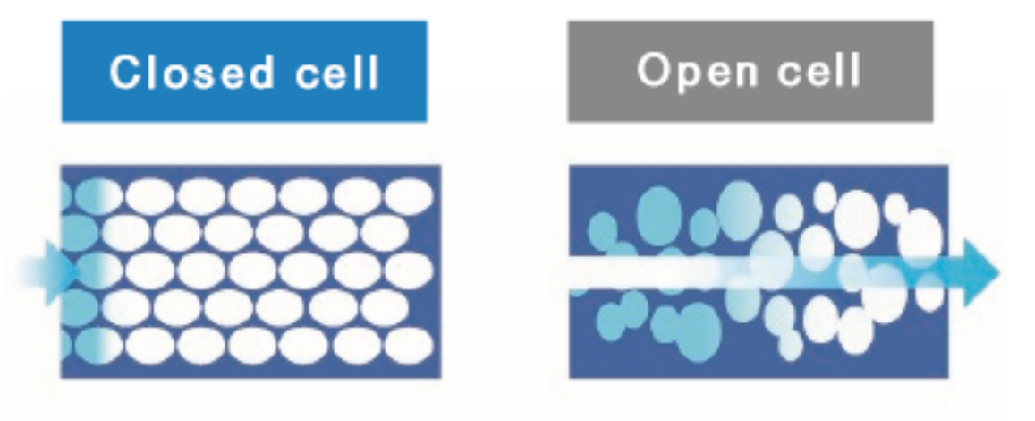

Chotsekeka-selo Foam

Mkati mwa mtundu uwu wa thovu, mkati thovu ndi palokha, osati ogwirizana wina ndi mzake (lotseguka-selo).Maselo otsekedwa satulutsa mpweya mosavuta.Chifukwa chake, amakhala olimba, amachira msanga mawonekedwe awo akamapanikizidwa, ndipo amakana madzi.

Zogwirizana ndi PE

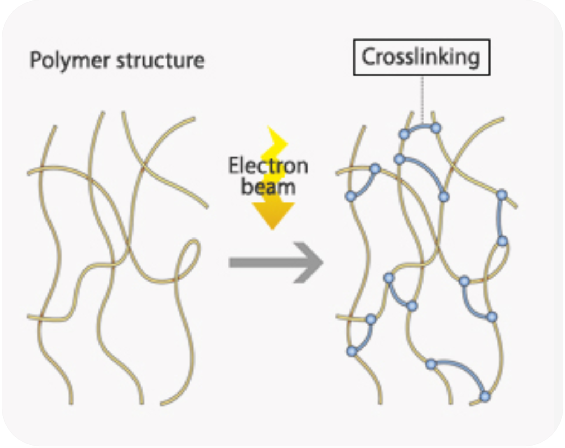

Zomwe zimaphatikiza unyolo wama cell a polyethylene.Crosslinking kapangidwe ka maselo bwino mphamvu, kutentha kukana, mankhwala kukana, etc. Njira amatchedwa crosslinking chifukwa unyolo yaitali maselo amafanana milatho.

Physical Cross-linked PE/PP

Ma elekitironi amathyola mamolekyu a maselo ndikupanga mawanga a polima.Irradiation crosslinking ndi njira yolumikizira madontho awa kwa wina ndi mzake.Poyerekeza ndi zinthu zomwe zimagwirizanitsidwa ndi mankhwala, zinthu zomwe zimagwirizanitsidwa ndi magetsi zimakhala zokhazikika komanso zogwirizana.Ubwino wake ndi wofewa komanso wosalala komanso wabwino pakukula kwamtundu.

Njira Yopangira

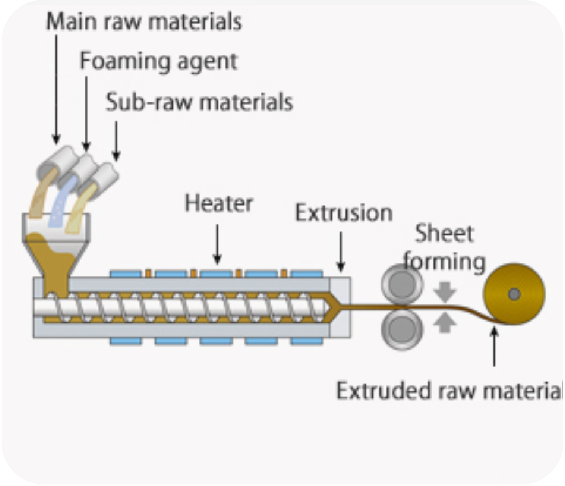

Extrusion

Zida zopangira (PE / PP) zimasakanizidwa ndi chowombera ndi zinthu zina ndikuzitulutsa m'mapepala.

Kuthirira

Kutulutsa ma elekitironi pa ma polima kuti apange zomangira zamamolekyulu.

Kuchita thovu

Mapepala amathiridwa thovu ndi kutentha, kupanga thovu ndi voliyumu mpaka nthawi 40.

Kukanika kwa Madzi/Kumayamwa Mphamvu

Kukaniza kwa Madzi / Mayamwidwe

Foam ya polyolefin-based resin-based based cell foam imakhala ndi mayamwidwe ochepa amadzi

Popeza polyolefin ndi lipophilic resin, ndi otsika-hygroscopicity zinthu.Maselo a IXPE/PP sali olumikizidwa, omwe salola kulowa kwa madzi, akuwonetsa kukana kwamadzi bwino.

Mphamvu

Zolimba koma zosinthika, zolimbana ndi kutentha kwambiri poyerekeza ndi thovu losalumikizana

Kuwoloka kapangidwe ka mamolekyu a polima ndi zomangira ngati zingwe zomangika kumalimbitsanso zomangira za mamolekyulu, zomwe zimapangitsa kuti pakhale ma mesh a molekyulu, kumathandizira kukana kutentha ndi mphamvu.

| Crosslinked | Zosalumikizana | |

| Mlingo Wokulitsa | Nthawi 30 | |

| Makulidwe | 2 mm | |

| Kuthamanga Kwambiri (N/cm2) *2 | 43 | 55-61 |

| Elongation (%) * 2 | 204 | 69-80 |

| Mphamvu ya Misozi (N/cm2)*2 | 23 | 15-19 |

| Max Operating Tem*3 | 80 ℃ | 70 ℃ |

Thermal Conductivity Thermal Insulation Heat Resistance

Thermal Conductivity

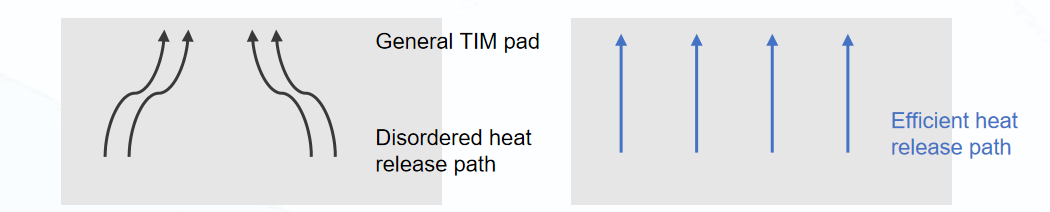

Moyenera bwino anakonza matenthedwe conductive filler amakwaniritsa mkulu matenthedwe madutsidwe

Timawongolera kalozera wa anisotropic thermal conductive filler kuti apange njira zotulutsira kutentha, kukwaniritsa matenthedwe apamwamba komanso kufewa.Kuphatikiza apo, zolemba zathu zakuthupi zimapangidwa ndi zida zotchingira magetsi zokha komanso utomoni wopanda siloxane, zomwe zimachepetsa chiopsezo cha kuwonongeka kwa zida zamagetsi kuti zikhale zotsika kwambiri.

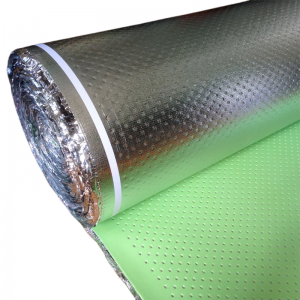

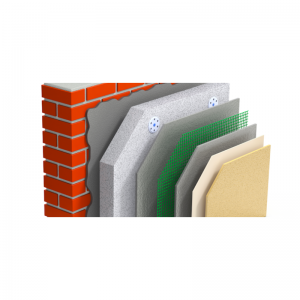

Thermal Insulation

Chithovu chokhala ndi mpweya wambiri wokhala ndi mpweya wocheperako zomwe zimapangitsa kuti pakhale kutsika kwamafuta komanso magwiridwe antchito apamwamba amafuta.

Maselo otsekedwa mu thovu amachepetsa kuchuluka kwa mpweya, kuchititsa kutentha pang'ono, komwe kumapereka chitetezo chabwino kwambiri chamafuta.Mosiyana ndi ubweya wagalasi ndi thovu lolimba, thovu limasinthasintha kwambiri komanso losavuta kuyiyika.Choncho, ndi yoyenera kwa insulators kudzaza malo ochepa kwambiri m'nyumba ndi makina osiyanasiyana.

Kukaniza Kutentha

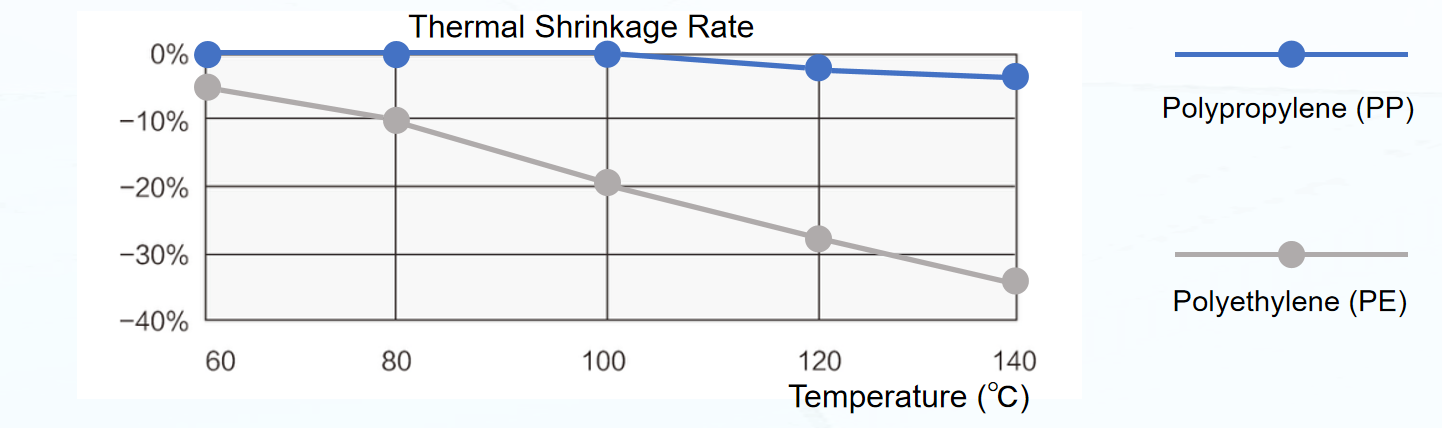

Ndi kukana kwambiri kutentha, utomoni wa polypropylene umakhala ndi kutsika pang'ono kwa kutentha ngakhale kutentha kwambiri

Mlingowo umayimira kuchuluka kwa chithovu chomwe chimasintha kukula kwake pa kutentha kosiyanasiyana chikatenthedwa popanda mphamvu yakunja.Ngakhale kuti thovu la polyethylene limapindika likatenthedwa kufika ku 80°C kapena kupitirira apo, thovu la polypropylene limatha kupirira kutentha kwambiri ndipo limachepa kwambiri ndi 3% kapena kucheperapo ngakhale pa 140°C.

Kusindikiza Luso Kusalala Kusinthasintha

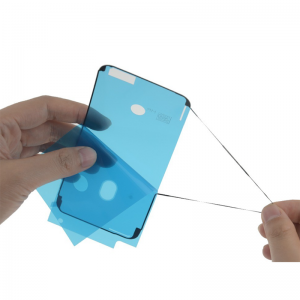

Kusindikiza Kukhoza

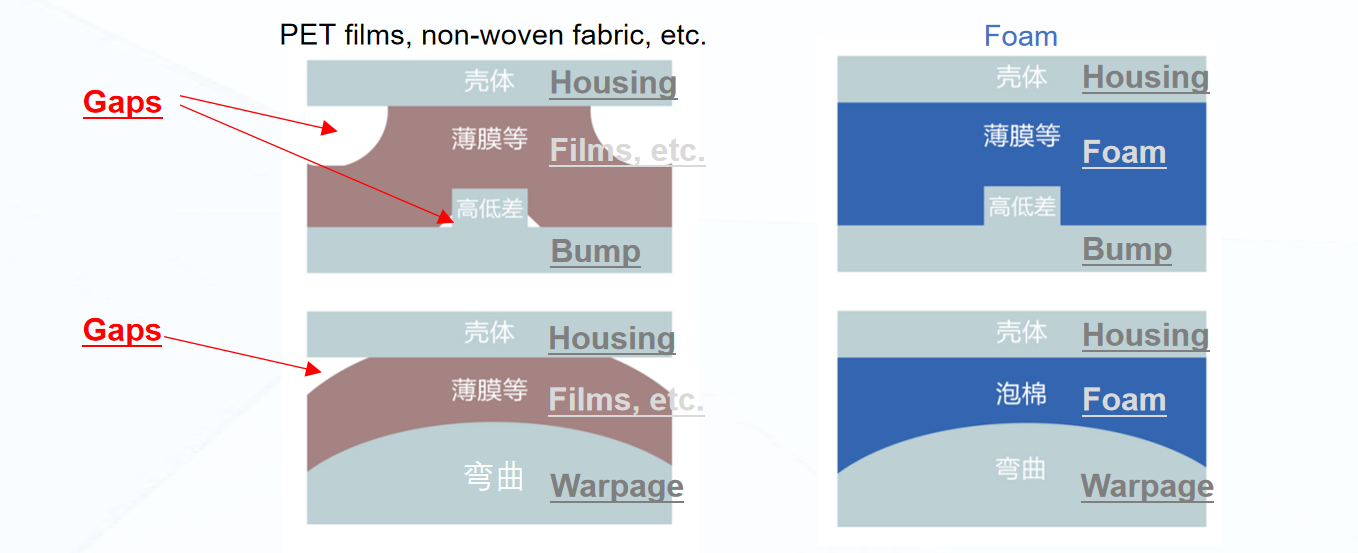

Ndi kusinthasintha kwake, thovu limasindikiza malo osagwirizana kapena akuthwa

Kusindikiza katundu wa sealer monga matepi amakhudzidwa kwambiri osati ndi katundu wa zinthu zakuthupi komanso kukhudzana kwake kwapafupi ndi malo osagwirizana ndi adherend.Chida chokhala ndi kusinthasintha kwakukulu chimachotsa mipata ndi adherend ndikuzindikira kusindikiza kwakukulu.

Yerekezerani ndi zinthu zina pa malo osindikizira

Chithovucho chimasindikiza malo osagwirizana ndikudzaza mipata mkati mwa nyumbayo

Kusalala

Malo owoneka bwino komanso oyeretsera poyerekeza ndi chithovu chophatikizika chamankhwala, choyenera kumamatira ndi kupaka

Electron beam crosslinking imathandizira ma elekitironi okhala ndi voteji yayikulu ndikuwatulutsa pamapepala.Ma elekitironi amtengowo amalowa mokhazikika komanso mokhazikika papepala lililonse, zomwe zimapangitsa kuti pakhale kulumikizana kolumikizana kuposa njira zina.Imalola ngakhale thovu lomwe limapanga malo osalala bwino oyenera kumamatira ndi kupaka.

Kusinthasintha

Kufewa kwamkati kwa utomoni ndi kapangidwe ka maselo otsekedwa kumapereka kukhazikika komanso kupindika koyenera

Selo la ma electron-crosslinked sheets lidzakhala ndi inflate mu ndondomeko yotulutsa thovu pambuyo pake.Maselo okhala ndi nthawi zosiyanasiyana zakukulira amapanga mawonekedwe otsekeka omwe ma cell onse amasiyanitsidwa ndi makoma.Maselo otsekedwa amakhala ndi mayamwidwe apadera komanso mayamwidwe odabwitsa.Pokhala ndi mayamwidwe abwino kwambiri ngakhale ndi makulidwe ang'onoang'ono, mapepala a IXPE/PP amagwiritsidwa ntchito ngati phukusi la zida zolondola.

Kugwira ntchito

Thermoformability

Katundu Wochepa Wachilengedwe

Makhalidwe Amagetsi

Kugwira ntchito

Wabwino mawonekedwe bata amazindikira zosiyanasiyana processing

Pogwiritsa ntchito thermoplastic polyolefin resin, thovu lathu limatha kusintha madzi a polima posintha kutentha.Ndi kutentha ndi kusungunuka, imatha kugwirizanitsa zipangizo zina kapena kusokoneza chithovu.Pogwiritsa ntchito kukhazikika kwa mawonekedwe pa kutentha kwa chipinda, imathanso kudulidwa mu mawonekedwe ovuta.

Main processing zitsanzo

● Kudula (kusintha makulidwe)

● Lamination (kuwotcherera kutentha)

● Kudula-kufa (kudula ndi nkhungu)

●Thermoforming (kupangira vacuum, kuumba atolankhani, etc.)

Thermoformability

IXPP imapirira kutentha kwambiri pakuwumba, kupangitsa kuti ikhale yozama kwambiri

Polypropylene (PP) ili ndi malo osungunuka kwambiri kuposa polyethylene (PE).Ndi kukana kwambiri kutentha ngakhale pa kutentha kwambiri akamawumba, PP akhoza kukwaniritsa zabwino zonse thermoformability ndi cushioning.Makamaka, PP imagwiritsidwa ntchito kwambiri pakupangira zida zamagalimoto zam'kati ndi matayala oteteza zipatso.

Katundu Wochepa Wachilengedwe

Zopanda halogen, palibe mpweya wapoizoni ukawotchedwa

Polyolefin ndi mtundu wa pulasitiki wopezedwa mwa synthesizing monomers (ie mayunitsi mamolekyu) ndi carbon-carbon awiri zomangira.Popeza ilibe ma halogen monga fluorine ndi chlorine, simapanga mpweya wapoizoni kwambiri ikawotchedwa.

Makhalidwe Amagetsi

Kuchuluka kwa mpweya mkati mwa maselo otsekedwa kumapereka mphamvu zabwino kwambiri za dielectric ndi chilolezo chochepa

Maselo otsekedwa, momwe mpweya wokhala ndi mphamvu zochepa za dielectric umatsekedwa m'malo ang'onoang'ono olekanitsidwa, amasonyeza mphamvu zapamwamba za dielectric.Kuphatikiza apo, polyolefin, yomwe ili ndi chilolezo chochepa poyerekeza ndi mapulasitiki ena onse, omwe amapangidwa m'mapangidwe okhala ndi mpweya amapereka chilolezo chochepa.